FLEETS

Sunvair Aerospace Group services a wide array of aircraft, both commercial & military, fixed-wing & rotorcraft

Commercial

- Airbus

- Boeing

- ATR

- Bombardier

- Embraer

Military

- Boeing

- Lockheed Martin

- Northrup Grumman

Rotorcraft

- Airbus

- AgustaWestland

- Boeing

- Erickson

- Sikorsky

Business Jets

- Falcon Jets

- Gulfstream

- Hawker-Beechcraft

everything you need in one place.

AVIONICS & INSTRUMENTS

"Repair not replace" is our motto. With extensive engineering capabilities in electronics and complex instruments, we can deliver a long-term solution to your repair needs.

Instruments

Avionics

- PCB Components

- Micro-mechanical

- Engineering Obsolete Components

- Analog/Digital Barometric Specialties

- Cost-optimized Supply Chain

- PC Boards

- Surface Mount Soldering

- Integrated Software Development

- Digital/Analog Interface Communications

- 485/422/429/1553 Arinc Data

Accessories

- Flight Critical Components

- Reliability Engineering to Increase On-wing Time

- Sub-assy Repairs

- Pitot-static, electo-pneumatic, electro-mechanical, refrigeration, and cabin systems

LANDING GEAR

"Quality is Our Pride" is Sunvair's founding motto, and carries on today, as Sunvair is known as the industry best for quality landing gear repair and overhaul.

Assemblies

Components

- Fully Dressed Gear

- Wiring Harnesses

- Hydraulic / Actuation

- Piping

- Side Struts

- Struts

- Pistons

- Cylinders

- Links

- Housings

- Sleeves

- Engine Mounts

- Carriages

- Hydraulic / Actuation

CARGO LOADING SYSTEMS

Mingo Aerospace is one of the most experienced and well-respected cargo loading system repair facilities in the world. We directly support many of the largest airline around the world, specializing in repairs and spares for Telair and Goodrich Collins components. Our technicians have many combined years of experience in repair and overhaul of OEM cargo loading systems. Mingo is the official North American repair facility for Telair Sliding Carpet® Loading Systems.

We maintain a large and diverse inventory of key components to support cargo loading systems which allows us to be able to provide world class turn-around-times, rotables, and ready-to-ship overhauled components to meet AOG requirements and advanced exchanges.

Mingo Aerospace is the only 3rd party repair facility in the world with full in-house capability for latest generation B787, B777F, B747F, and A350 Cargo Loading Systems.

- PDUs (Power Drive Units): Repair, Exchanges and Surplus Sales

- Cargo Rollers & PMA rollers: Repair and Surplus Sales

- Stop Locks

- Rollout Stops

- Lateral Guides

- Linear Actuators

- Guides

- Ball Panels

- TELAIR Sliding Carpet® Loading Systems

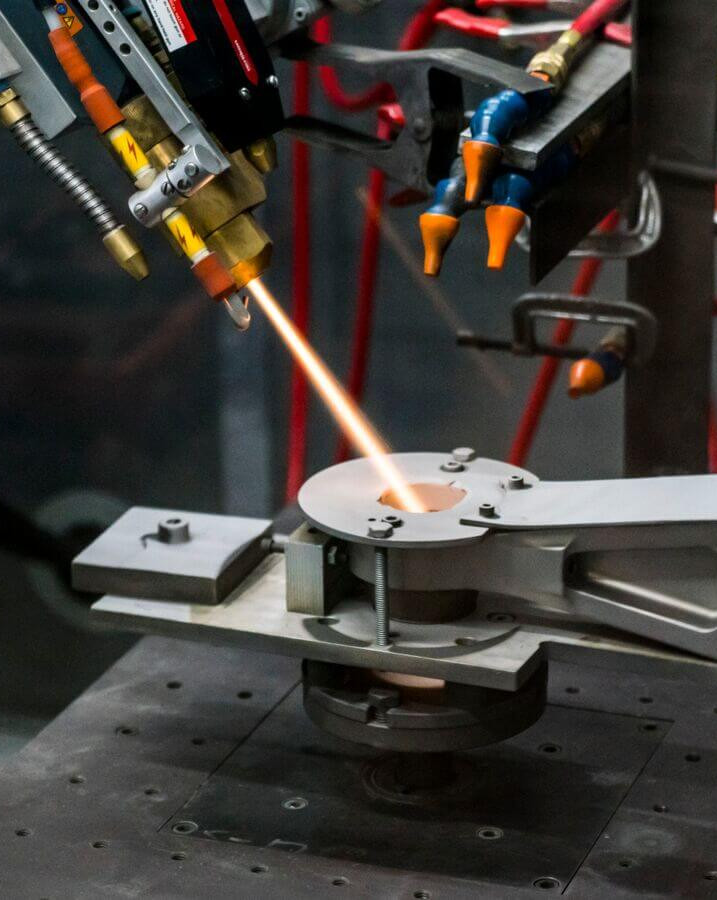

THERMAL SPRAY

Guaranteed industry leading turn-around-times and pricing

Mingo is a full-service Napcap and US Air Force approved HVOF Thermal Spray facility with one-stop-shop capability. Our in-house CNC-Grinding, Plating, Shot Peening, Painting and Non-Destructive Testing allow Mingo to provide the best turn-around-times in the world for our Thermal Spray product line. Our Quality System ensures the highest standards are achieved on every job.

We directly support landing gear MROs, The US Air Force, and USAF Tier suppliers.

Mingo Aerospace’s leadership team has many years of collective experience in HVOF thermal spray technology and have been highly involved in collaborating with the industry OEMs since its early days of adoption into the aerospace world as a wear resistance coating. Mingo employs a highly qualified thermal spray department that is invested in consistently providing the highest quality while maintaining industry leading turn-around-times.

Target parts and platforms:

- Flight Control: Flap Tracks & Slat Tracks

- Landing Gear: Bearing Races, Trunions, Hanger Links, Retraction Links

- Boeing: 737NG, 777, and 787

- Airbus: A350

- Embraer

- Military: Various

For a complete list of parts or to search for a specific part capability, please use our Part Capabilities Search.

PLATING

Supporting a full range of plating and surface technologies

Processes

Inspection

- Hard Chrome

- Sulfamate Nickel

- LHE Cadmium

- Brush Cadmium

- Chem Film

- Shot Peen

- Nital / Temper Etch

- Eddy Current

- Mag Particle Inspect

- Fluorescent Penetrant Inspection

Specialized TOOLING

We design and manufacture custom electroplating fixtures, primarily for hard chrome, nickel and cadmium electroplating. We also provide on-site services, including set-up and training.

Hard Chrome Plating Fixtures

- No-Mask design

- Conforming anodes

- Rapid and easy set-up

- Exact centering

- Multiple surfaces plating

- Electrical connectivity/conductance

- Anode encasement

- Reduced air exhaust obstructions

Nickel and Cadmium Electroplating Fixtures

- Conforming and no-mask conforming anode systems

- Pure nickel, cadmium, steel, stainless steels, platinum and platinized titanium anode materials tooling

- Out-of-tank flow-style anode plating systems for large parts

Learn more about the Sunvair Aerospace Group

Our values, people, and quality drive our reliability

ABOUT SUNVAIR AEROSPACE GROUP Learn more about Sunvair Aerospace GroupExplore our state of the art facilities

We have built out some of the finest facilities in the world to keep you flying safely.

EXPLORE FACILITIES Explore Sunvair AerospaceGroup facilities